- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

ART210R

RobotCAM

Product Description

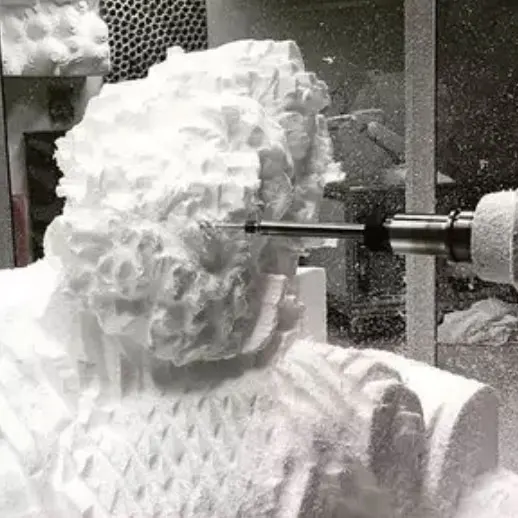

3D CNC Sculpture 6 axis 7 Axis Milling Robot Arm Milling Machine For Wood Foam Stone styrofaom mould

6 axis 7 Axis Milling Robot Arm for cutting curved surface chair wood

We can offer a complete turnkey solution for milling projects:

CNC machining robot

KUKA Robot Technical Parameters:

| Load (refers to the load of point P at the foremost end of the 6th axis) | 210kgs | |

| Additional load on the arm | 50kgs | |

| Total load | 260kgs | |

| Weight | 1068kgs | |

| Motion axis | 6 | |

| Max.envelope | 2696mm | |

| Repeat accuracy | 〈+/-0.06mm | |

| Flange (on the 6th axis) | DIN ISO 9409-1-A50 | |

| Controller | KRC4 | |

| Installation position | On the ground | |

| Motion parameters of each axis | Range of motion | Speed |

| Axis 1 | +/-185° | 123°/s |

| Axis 2 | -5°/-140° | 115°/s |

| Axis 3 | +155°/ -120° | 112°/s |

| Axis 4 | +/-350° | 179°/s |

| Axis 5 | +/-125° | 172°/s |

| Axis 6 | +/-350° | 219/°/s |

In the cell is included the following:

KUKA KR240 or KR210 with a KRC2ed05 controller, totally refurbished by our expert KUKA technicians

A spindle with automatic tool changer, air or water cooled

Basic set of tools of 5 bits and 5 cones that would allow you to do almost any jobs

A tool holder station with sensors and calibration tool

Complete Sprutcam Robot Licence (www.sprutcam.com)

Installation, basic training for KUKA robot operator, introduction to Sprutcam training

Product Details :

Application Field

|  |  |

Carbon fiber milling With a robotic system perform the carbon fiber trimming process provides a low level noise and less maintenance periods. | Foam milling Great programming ability so you can use a variety of tools that shape any material providing profitability in the elimination of it. | Robotic hot wire cutting You can perform 2D and 3D modeling on any manageable material with a robotic milling cell, allowing hot wire cutting to provide a perfect and fast finish by polishing. |

|  |  |

| Marble Stone machining Robot The marble cut is optimized thanks to the use of robotic systems that offer a tool with greater versatility making the cut with maximum quality and reducing time and effort. | Robot on linear track Industrial robot on linear track provides greater precision, high speed, self-aligning capability, stiffness and increased performance. | Orthopedic milling The automation in the medical industry is used diversity of materials such as aluminum, titanium, stainless steel etc ... in this application, the speed and advanced technology offered by the milling and turning system is prime. |

|  |  |

| Polystyrene milling The metal milling with industrial robots makes it possible to elaborate large-volume complex parts of small dimensions with high quality and precision. | Robotic art milling Through a simple interface the robotic arm can shape any wooden surface creating a perfect work of architecture. | Metal machining The metal milling with industrial robots makes it possible to elaborate large-volume complex parts of small dimensions with high quality and precision. |

|  |  |

| Milling architecture Through a simple interface the robotic arm can shape any wooden surface creating a perfect work of architecture. | Floating deburring Solution For deburring of non-standard workpieces such as die-casting parts and workpieces, how to make the workpiece fit the surface processing without overcutting or cutting, | Yacht robot milling Nautical machining is a challenging task but include industrial robots has become a cost-effective manufacturing solution since through a simulation program can analyze and design the process to be performed with large-scale dimensions. |

Video

3D CNC Sculpture 6 axis 7 Axis Milling Robot Arm Milling Machine For Wood Foam Stone

Sample

Milling robot working Wood carving sample

Robot cnc milling Foam