- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

KR240R

Product Description

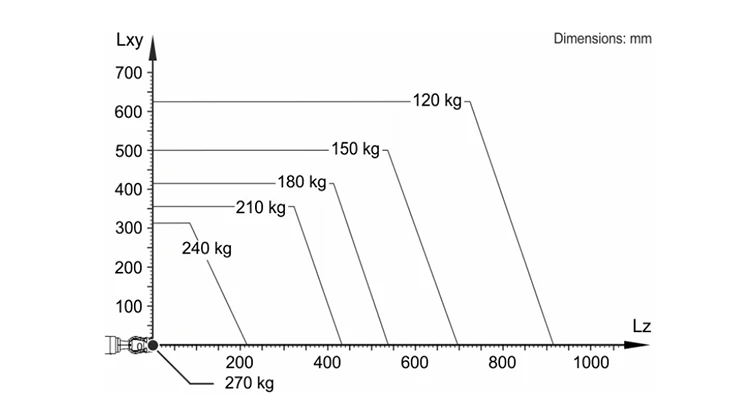

| Load (refers to the load of point P at the foremost end of the 6th axis) | 210kgs | |

| Additional load on the arm | 50kgs | |

| Total load | 260kgs | |

| Weight | 1068kgs | |

| Motion axis | 6 | |

| Max.envelope | 2696mm | |

| Repeat accuracy | 〈+/-0.06mm | |

| Flange (on the 6th axis) | DIN ISO 9409-1-A50 | |

| Controller | KRC4 | |

| Installation position | On the ground | |

| Motion parameters of each axis | Range of motion | Speed |

| Axis 1 | +/-185° | 123°/s |

| Axis 2 | -5°/-140° | 115°/s |

| Axis 3 | +155°/ -120° | 112°/s |

| Axis 4 | +/-350° | 179°/s |

| Axis 5 | +/-125° | 172°/s |

| Axis 6 | +/-350° | 219/°/s |

|  |

Italian Hiteco Spindle 1. The electric spindle can adopt high-speed grease and oil mist lubrication according to different speeds. 2. The temperature rise caused by the high-speed rotation of the electric spindle is eliminated by the water cooling circulation system. 3. It has the advantages of high precision, high rigidity, high efficiency, large output power, low noise, etc., and the speed is 12000 rpm/min. 4. The use of universal HSK F63 standard tool holders can meet customers' quasi-change use of different processing tools. | Teach Pendent Touch screen, graphics assistance, flexible interaction. The more powerful the robot is, the more important the intuitive robot operation interface is. The new KUKA smartPAD shows how to control the robot intuitively with the best effect on the super high-definition non-reflective touch screen. The intelligent interactive dialog window clearly shows the various processes to the user. At any moment, the user will be provided with the operating elements that they just need at that moment. Its purpose is to draw the user's attention to the most important factors so that it can work intuitively, simply, quickly and effectively. Really realize comprehensive intelligence. |

|  |

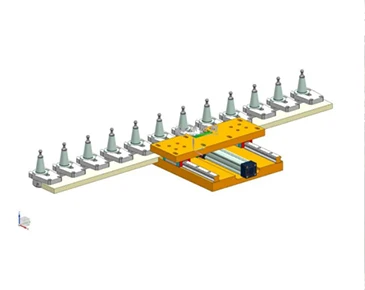

Linear ATC System The rotary table is a single-axis positioner, which is mainly composed of a positioner frame, a servo drive motor, a precision reducer, a turning plate, a lifting roller frame, a fixture and a control system. Among them, all welded structural parts are assembled by steel plates and profiles. All welds are welded according to the requirements of equal-strength welds. After welding, they are annealed to remove welding stress and effectively prevent processing deformation. The engraving robot composes a 7-axis linkage automatic engraving system, which can greatly increase the size of workpiece engraving and increase labor productivity. | Open KRC4 control system More efficient, safer, more flexible, and most importantly, more intelligent. The innovative concept of KR C2/C4 has laid a solid foundation for the future of automation. Reduce the integration, maintenance and maintenance costs of automation. And at the same time lastingly improve the efficiency and flexibility of the system. So KUKA has developed a new system architecture with a clear structure and focusing on the use of open and efficient data standards. All safety control, robot control , motion control, logic control and process control integrated in this system architecture have the same data foundation and foundation Facilities can be used and shared intelligently. |

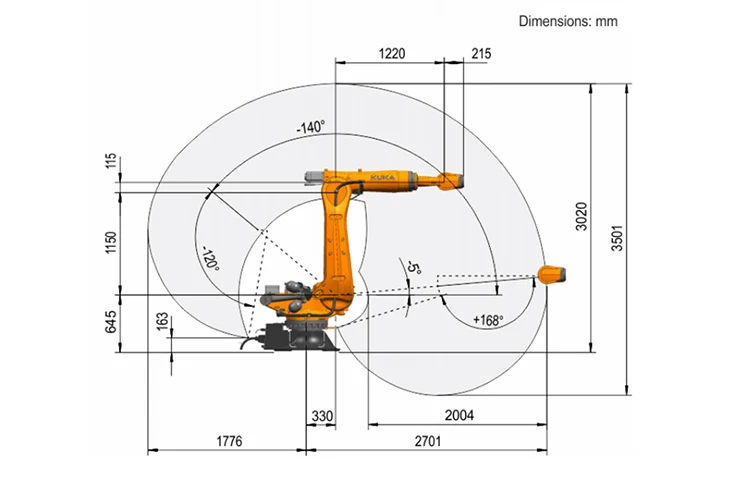

Workspace graphic

The marble cut is optimized thanks to the use of robotic systems that offer a tool with greater versatility making the cut with maximum quality and reducing time and effort.

|  |